Smartphones have come a long way in the last decade. Especially in terms of the processors. The amount of innovation that goes into designing a smartphone processor is incredible. We all have seem processors get smaller and more powerful and power efficient as well. 14nm, 12nm, 10nm, 8nm, and finally 7nm. The new iPhone’s i.e. iPhone 11 and iPhone 11 Pro come with the A13 Bionic processor which is based on the 7nm process.

But what does the future hold? Where are smartphone processors headed? 5nm, 3nm? Well, let’s find out.

How are Smartphone Processors Made?

Smartphone processors are made by a process called as lithography. The processors are basically printed onto a silicon wafer using lithography.

The most widely used technology to manufacture processors is DUV Lithography or Deep Ultraviolet Lithography. Its been used by chipset manufactures across the globe for more than a decade now. Let’s see how DUV Lithography works.

Deep Ultraviolet Lithography (DUV)

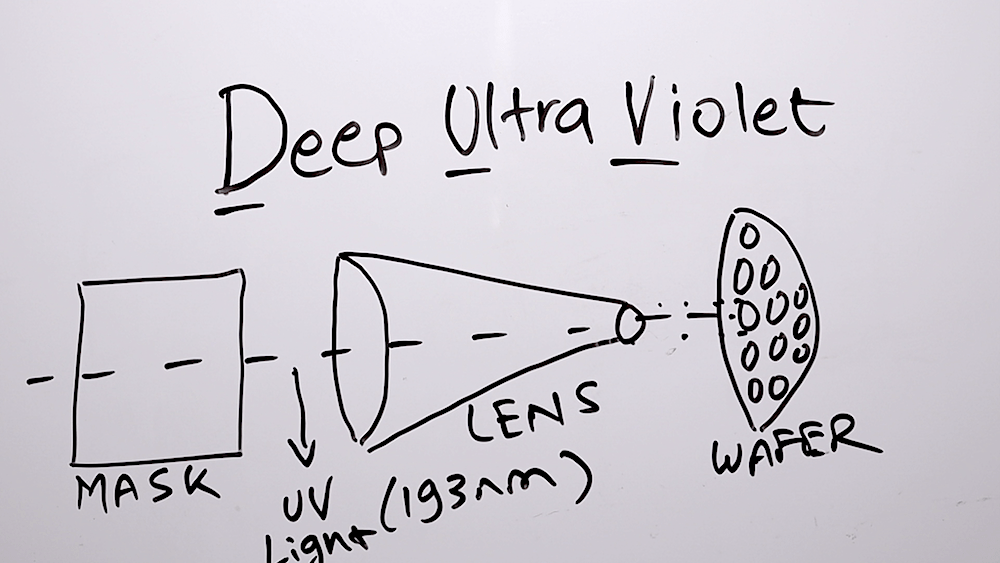

Deep Ultra Violet Lithography or DUV works in the following way:

- So first up there is a mask or a blueprint of the processor that needs to be printed. This mask or blueprint is pretty big in size as compared to the actual processor. The case is bigger so that it is easy to design it. Manufactures spend a lot of time and money in perfecting the mask because that’s the main component and the processor completely depends on the mask.

- The next component is a lens. This lens is used to project the image of the mask onto the silicon wafer. The lens also shrinks down the image of the mask to the required processor size.

- The third and final component is a silicon wafer. The processor is printed on this silicon wafer. Printing is done with the help of a UV Light with a wavelength of 193nm. This UV Light is produced with the help of a laser. So it basically passes through the mask, then through the lens and finally the processor is printed onto the silicon wafer.

Please note that this is a very basic explanation of DUV Lithography. There are many complex steps involved in DUV Lithography and you can learn a lot about it.

Problem with DUV Lithography

Now the problem with DUV Lithography is the wavelength of the UV Light. It is 193nm and because of that smaller processors like 7nm or 5nm are difficult to print. The 193nm wavelength of the UV Light is the main reason why there was a need for a better technology to replace DUV. That’s where EUV Lithography or Extreme Ultraviolet Lithography comes in.

Extreme Ultraviolet Lithography (EUV)

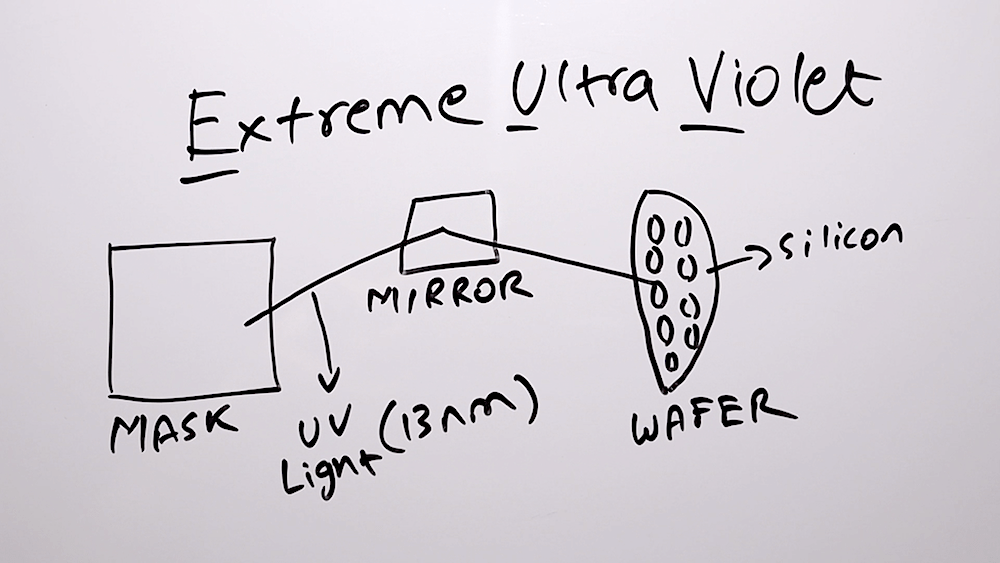

Here’s how Extreme Ultraviolet Lithography or EUV works:

- Just like DUV, EUV also has a mask or a blueprint. The blueprint is very important and manufactures keep them extremely clean and dust free.

- Here’s where EUV differs from DUV. Extreme Ultraviolet Lithography uses a UV Light with a wavelength of 13.5nm. Yeah 13.5nm. EUV is almost 14 times better than DUV. Anyway, because of the 13.5nm wavelength of the UV Light, lenses cannot be used because the will absorb the light and won’t let it pass through. Hence instead of lenses, mirrors are used. These mirrors project the image of the mask onto the silicon wafer.

- Finally the third component is again the same. A silicon wafer where the actual processor is printed with the help of the above mentioned 13.5nm UV Light.

Advantages of Extreme Ultraviolet Lithography or EUV

Because of the 13.5nm UV Light, EUV can be used and is preferred to print smaller processors like 7nm and 5nm. EUV makes it possible to print smaller processors and that is excellent. Manufacturers like TSMC (Taiwan Semiconductors) and Samsung have already started using EUV Lithography in their manufacturing process.

It is juts a matter of time until all the processor manufacturers out there start using EUV Lithography for making their processors.

So yeah, with the help of EUV Lithography we are going to see smartphone processors get better and more powerful than ever. Some people might argue that, “do we actually need that much performance on our smartphones?” Why not, right? Software hasn’t caught up to the hardware as of yet, but when it does, the hardware should already be pretty good. “Hardware shouldn’t be a limitation for Software.”

Anyway, to have a more visual explanation of all this, you can watch our video on the same topic:

How To Remove Bloatware From Any Xiaomi Devices (Without Root): Easiest Way!

Fantastic Windows 10 Icons And How To Install Them

How to Install and Uninstall Kernels in Android – Custom Kernels

The Minimalist Setup for Android Devices

Realme Watch 2 Launched: A Worthy Upgrade?

iQoo 7 Launched: Price, Specifications & Launch Date in India

Mi 11 Ultra: Into The Reckoning !!!

Surface Laptop Go Launched in India: The Most Affordable Surface!